Horizontal Conveyor Dryers

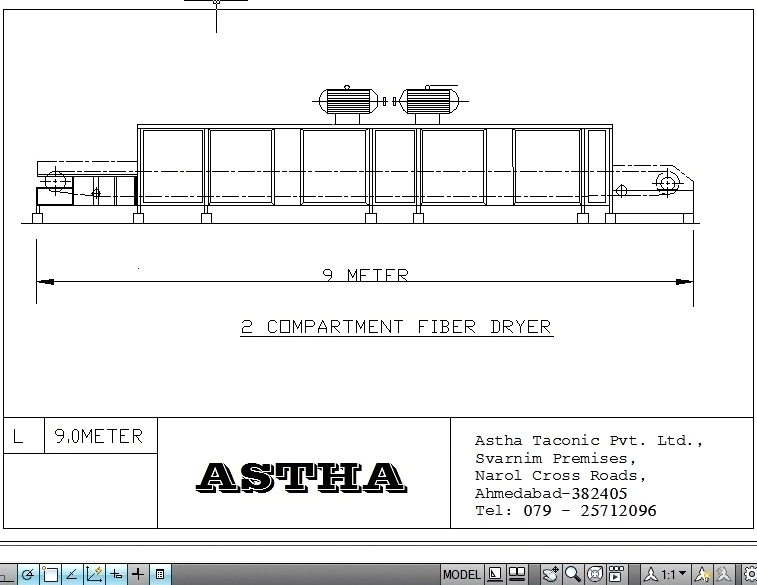

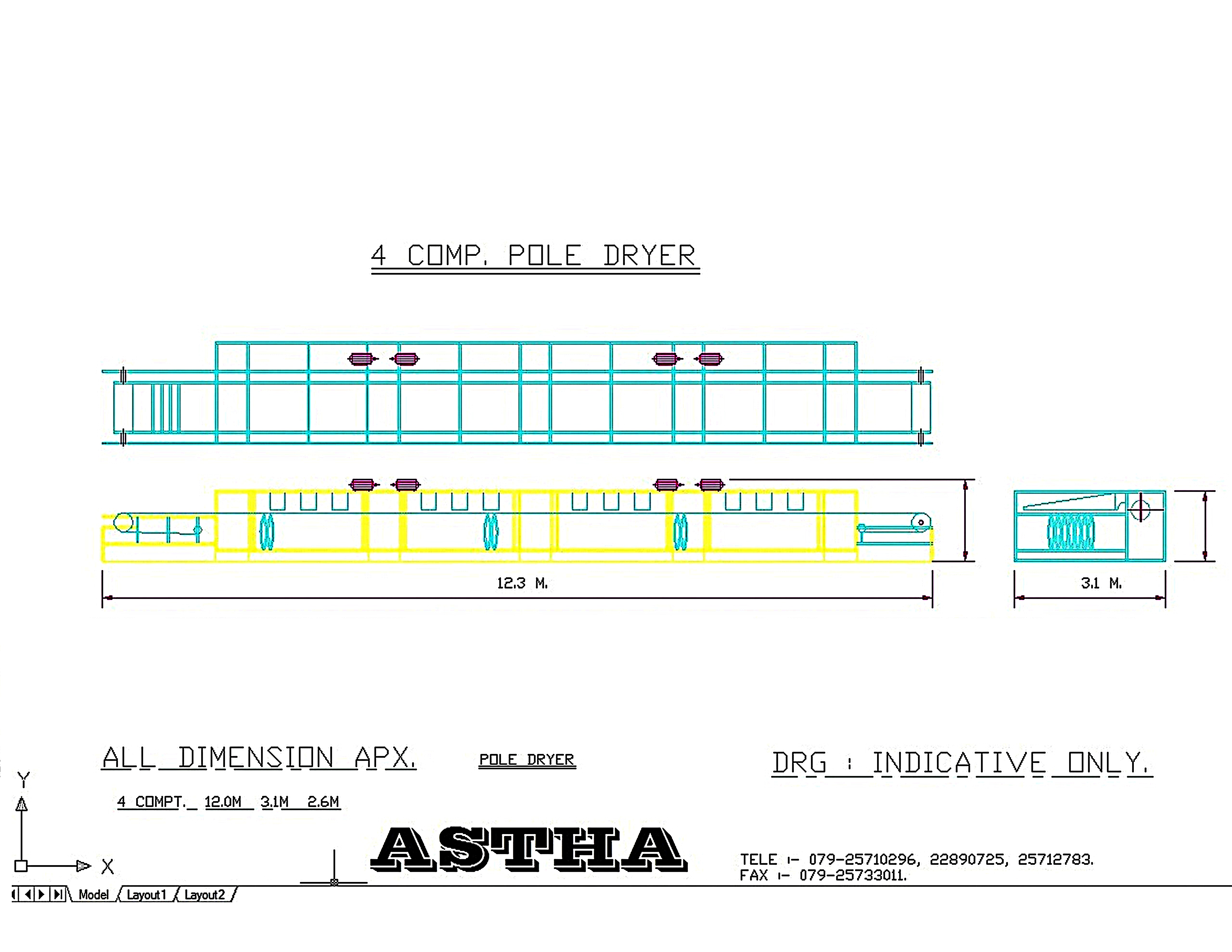

CONTINUOUS HORIZONTAL CONVEYOR FIBER DRYER, for drying fiber comprises mainly 2 or more insulated compartments, a metallic end-less partially interlocked perforated plate conveyor, assembled together on the conveyor chain and air ventilation system, comprising the centrifugal blowers, vertical draft air ventilation ducts and the heat exchangers, suitable for providing the even and desired flow of hot air on the fiber. The hydro-extracted fiber is loaded on the entry side and will pass through the dryer, before exiting at the other end. The width of the dryer can be customized as per the space availability with the buyer and the drying capacity can be increased from time to time by installing additional compartments as and when desired.

A basic three step pulley drive is provided for controlling speed up to 3 levels. A suitable Variable Speed Controller / Inverter Drive can be provided at an extra cost, to control the speed of the conveyor, in case the customer wants to dry different variety of fiber viz. Acrylic, Viscose, Wool, Cotton, Melange, Polyester, etc. having different retaining moisture capacities, that requires the regulating of the stay time of the fiber in the drying zone.

A YARN DRYER suitable for drying a variety of hydro-extracted yarn made from Coir, Sisal, Silk, Wool, Cotton, etc. almost similar as the fiber dryer is supplied with slight modifications in the conveyor plates and air ventilation system.

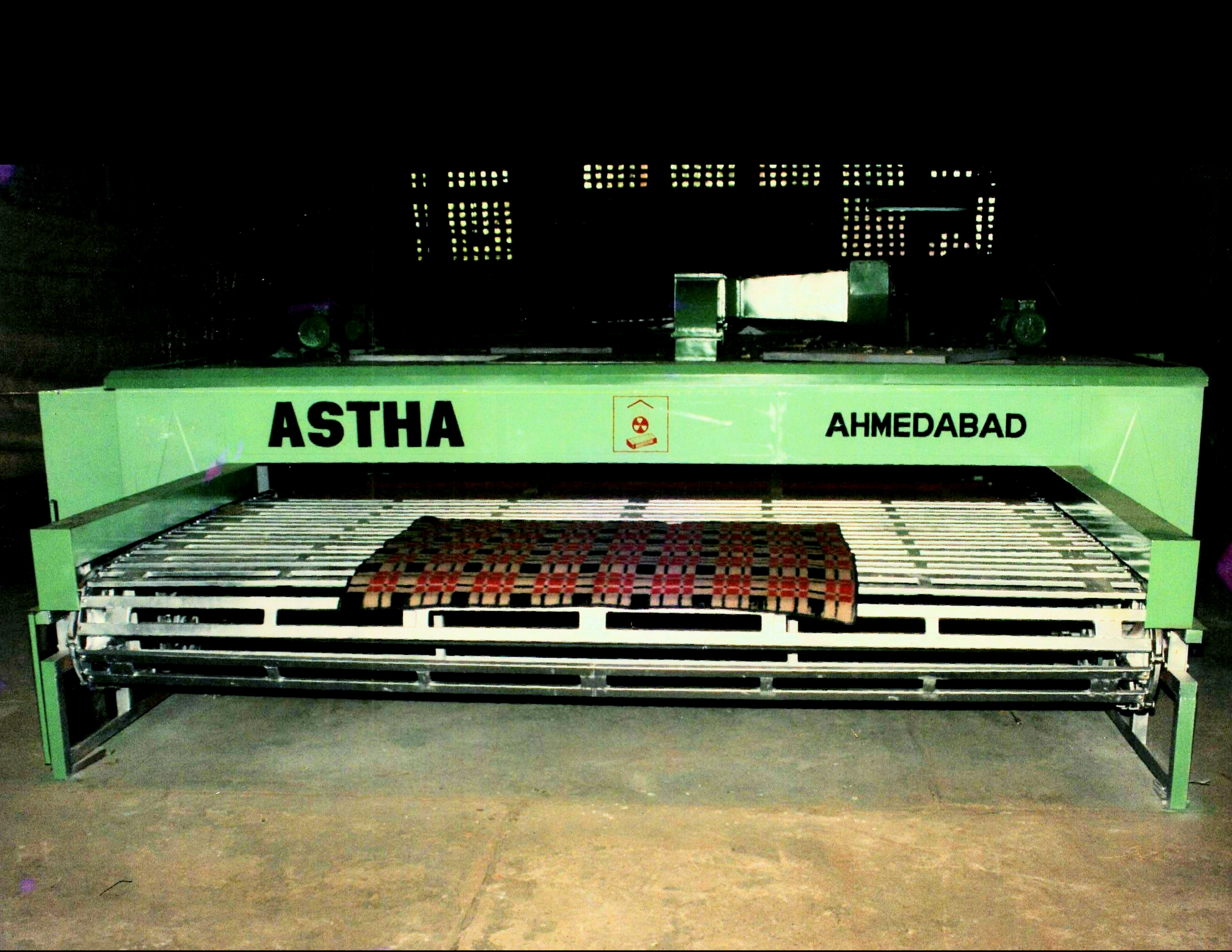

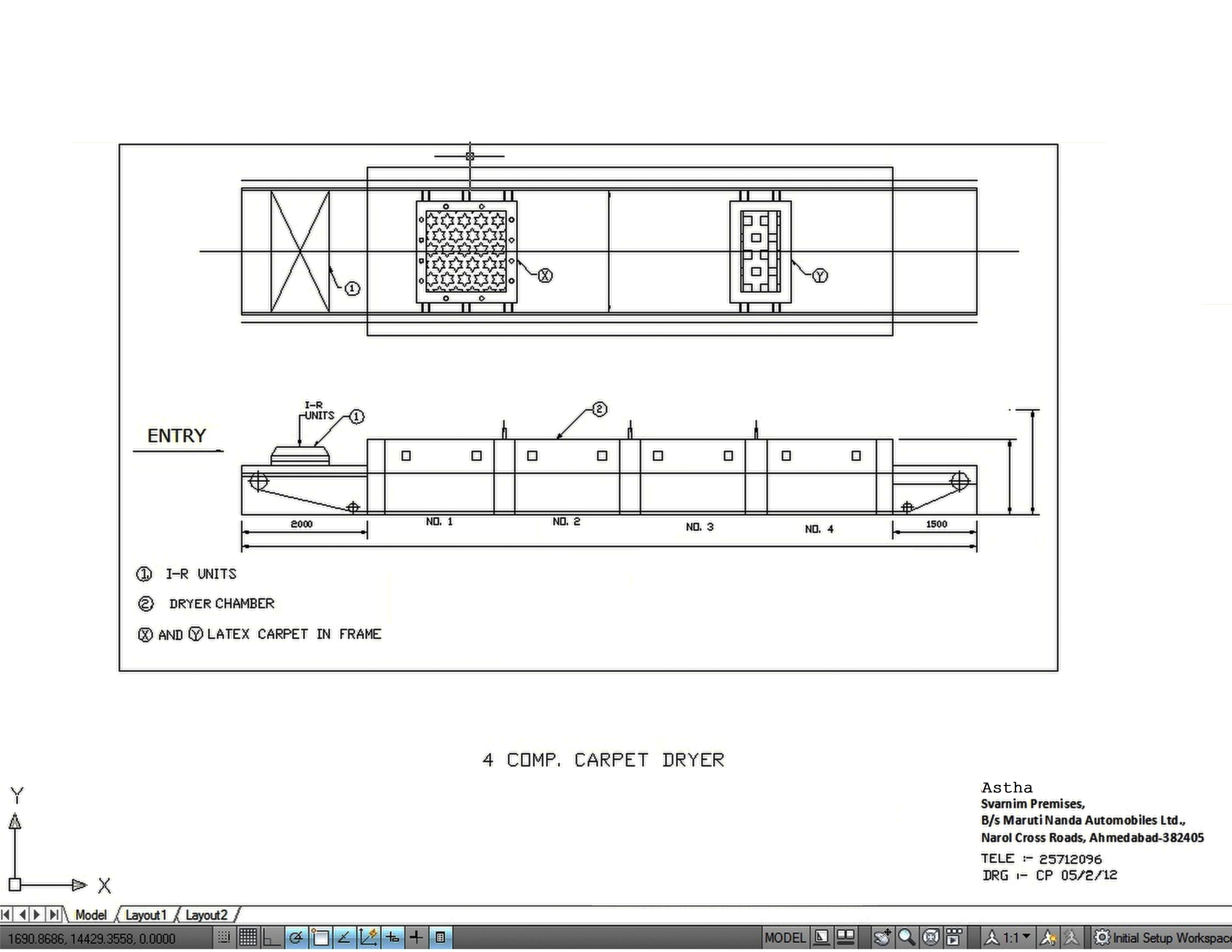

CONTINUOUS HORIZONTAL CONVEYOR CARPET DRYER, consists of mainly 2 or more insulated compartments, a metallic end-less conveyor made of square tubes assembled together on the conveyor chain and the top and bottom zone air ventilation system comprising centrifugal blowers, vertical draft air ventilation ducts and the heat exchangers, suitable for providing an even and desired flow of hot air on the carpets. The carpet is loaded on the entry side and will pass through the dryer, before exiting at the other end. The multitude of variations possible in terms of machine width as well as in terms of heating input mediums, enable custom made solutions for different line and size configurations. Besides, the production capacity of the dryer can be increased by adding additional compartments, as and when desired, as per the requirement of the clients.

Variable Speed Controller / Inverter Drive is provided along with the electric control panel, in the dryers, for efficient regulation of the conveyor speed. This helps the customer to efficiently and economically dry carpets made from a variety of textiles viz. Wool, Cotton, Silk, etc. which have different inherent capacities of retaining moisture, which requires controlling of the stay time of the carpets in the drying zone, by controlling the speed of the conveyor itself.

Optionally, at an extra cost, all the above dryers can be equipped with Efficiency Control Systems, whereby the hot air flow in each of the compartments can be separately controlled for further efficiency depending upon the base material being dried.