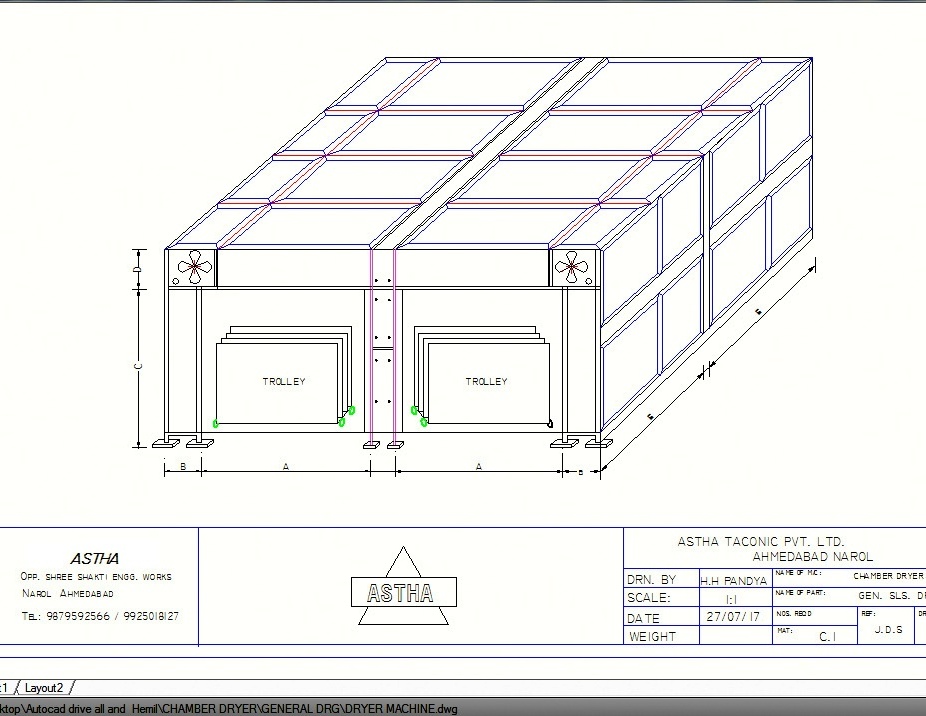

Chamber Dryer

BOOK CASE MODEL CHAMBER TYPE CARPET DRYER is an insulated chamber, consisting of load bearing trolleys and horizontal draft air ventilation system made up of centrifugal blowers and radiators. The latexed carpets are loaded on the specially designed load bearing trolleys, suitable for holding up to 30 carpets per trolley at a time and rolled on inside the chamber. Once the loading of the trolleys inside the chamber is over, the chamber doors are closed and the air ventilation system for drying the carpets is activated. The specially designed air ventilation system covers the full length, width and up to seventy-five percent height of insulated side walls of the chamber, as such ensuring an even and thorough flow of hot air through the carpets stacked on the trolleys, and at the same time eliminating the wastage of the energy input in the chamber. On completion of the suitable batch time the air ventilation system is de-activated and the trolleys with dried carpets are rolled out and new set of trolleys loaded with carpets are rolled on inside the chamber.

With a multitude of variations possible in terms of the Machine & Trolley length, width and height, we can supply customer specific machines, customized in accordance with the space availability, size of the carpets and production requirement at the customers end.

This Dryer can also be customized to fit in rods to additionally hold Hank Yarn for the purpose of drying, if required by the client.